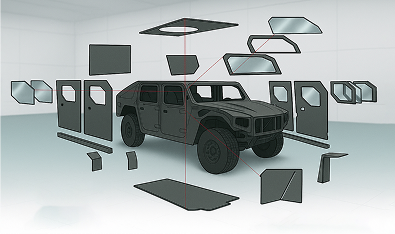

Third-Party Ballistic Testing, Certified for Operational Deployment

At AAT ArmourTech, protection is never just a promise; it’s proven. Every armoured vehicle we build uses materials certified through rigorous third-party testing by ISO-accredited labs and approved by the Inspectorate of Armaments (IoA).

We do not perform in-house ballistic testing. Instead, we source and verify all materials, including ballistic steel and transparent armor, against the highest international standards.

Our Testing Standards

All protective components are certified to meet or exceed

EN 1063

(B6/B6+ Transparent Armour)

CEN 1522

FB6+ (Opaque Armour)

UL 752

Level 8–10

STANAG 4569

Level 1–2 (Blast protection for light tactical vehicles)

Each build includes traceable documentation:

- Ballistic test logs

- Third-party certification reports

- Material origin and compliance papers

Request Sample Certification Packs For your procurement file or RFP requirements.

What We Prioritize in Ballistic Protection

We assess core protection features through controlled and repeatable testing procedures:

Resistance to High-Calibre Ammunition

Certified materials withstand 7.62×51mm NATO FMJ and comparable threats.

Multi-Hit

Endurance

All armour solutions are designed for sustained impact performance, not just single-shot survivability.

Structural Integrity Across Armor Types

Both opaque and transparent components maintain strength under pressure and across impact zones.

Understanding B6 Protection

B6-rated armor is one of the most trusted levels in civilian and security applications. It is engineered to stop 7.62×51mm NATO FMJ and high-powered rifles used in conflict-prone zones.

This level offers a critical balance between ballistic integrity, vehicle mobility, and visibility, ideal for convoys, executive fleets, NGOs, and high-risk transport units.

All AAT ArmourTech vehicles can be configured to meet B6/B6+ requirements. Custom solutions are available on request.

Who Relies on Us

Private Security & Convoy Teams

Depend on our armoured vehicles for secure, tactical mobility in high-risk zones.

Government

Transport Units

Use our fleet for reliable protection during official and diplomatic missions.

NGOs & International

Agencies

Choose our solutions to safeguard humanitarian teams and aid delivery operations.

Executive Protection

Services

Rely on discreet, high-performance armouring to ensure VIP safety on the move.

Our Approach

We follow a practical testing approach informed by global standards while focusing on field-ready performance. Materials like high-hardness, composite panels, and bullet-resistant glass are evaluated in-house and through third-party validation when required.

Why Certification Matters

We take ballistic standards seriously. That’s why all steel, composite, and glass materials used in AAT builds are:

- Lab-tested by certified ballistic facilities

- Inspected and approved by the IoA

- Backed by complete documentation for client assurance and auditability

Get in Touch | Request Certification Pack

Let’s help you deploy protection with confidence.